Brief Introduction:

Vehicle control technology is integrated into this series controller to provide efficient control of

the three-phase AC motor for the vehicle power drive system, providing the

most cost-effective design for vehicle developers and providing a flexible, comfortable and

safe handling experience for vehicle drivers and passengers.

Features:

●Applicable to Induction motor and PMSM

●To gain higher power density and overload capacity,SMD MOSFET and aluminum

plate cooling technology are adopted

●The power supply of control signal can be provided by12VDC or power battery

●High-performance vector control algorithm to achieve full speed range of motor

speed and precise torque control, improving vehicle power performance and comfort

●Flexible parameter adjustment function meets theexcellent

●Multi-functional I/O terminals, meeting the requirements of different applications

●Integrated high voltage pre-charge circuits, improving the all-in-one design

●Natural cooling, force air and liquid cooling are adopted, covering overall power range

●Customized software available for meeting different requirements of customers

●CAN bus communication and software update by computer programming

Typical Application:

●Applicable to all-electric or hybrid vehicles powered by rated voltage of battery 60 ~ 144 VDC

●Applicable to short-distance passenger cars, sightseeing cars, logistics vans,

sanitation vehicles andmaterial handling vehicles and other electric vehicles

Key technical features:

Electrical characteristics

| Auxiliary power voltage |

6~16V DC |

|

| Rated battery volt |

48V DC |

Support 72V and 48V battery |

| Input volt range |

24V~72V |

|

| Rated output current |

80A |

|

| Peak output current |

280A (3s) |

|

| Rated output power |

2.5kW |

|

| Peak output power |

5kW |

|

| Highest efficiency |

≥98% |

Rated condition |

| Output freq range |

0.00~600Hz |

|

Mechanical characteristics

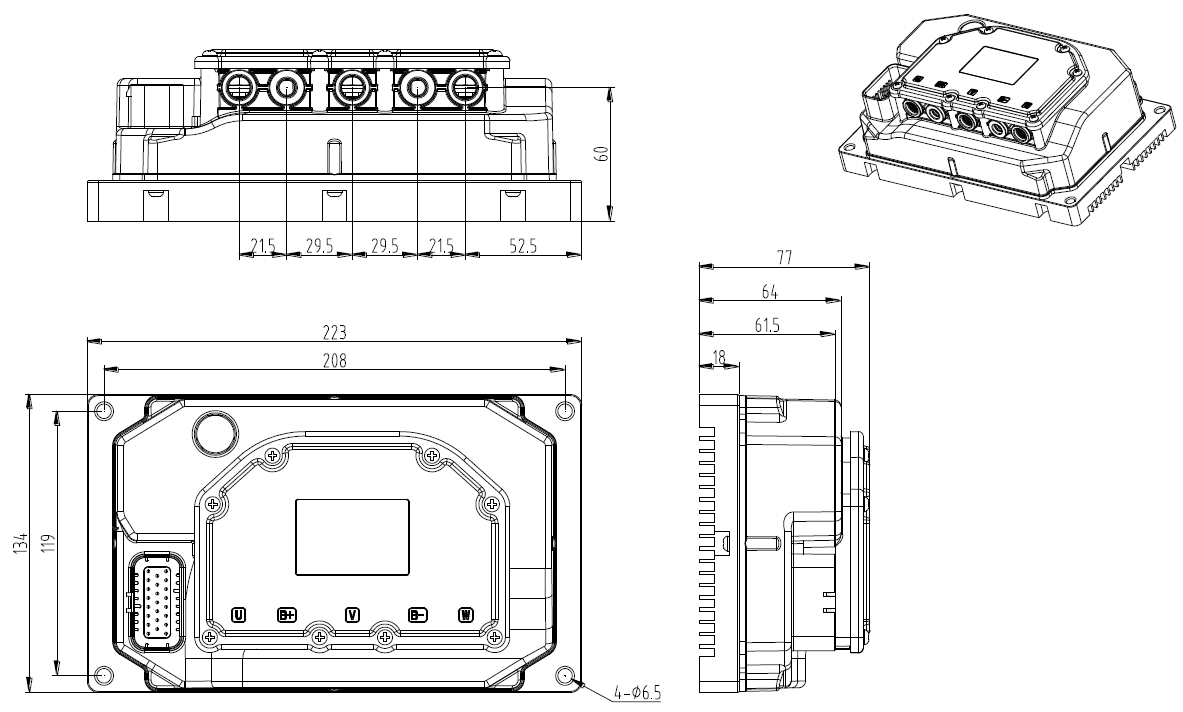

| Dimensions |

223*134*77 |

Please read external dimension below for more details |

| Installation dimensions |

L*W-Φ=208*119-4Φ6 |

Please read external dimension below for more details |

| Screw torque of protection cover |

M4*12,1.4Nm |

|

| Screw torque of power terminals |

M8*(16~20),14~16Nm |

B+、B-、U、V、W |

| Screw torque of bottom installation plate |

M6,19~21Nm |

|

| Cooling method |

Natural Cooling |

Air duct is needed

|

Control characteristics

| Control Mode |

Vector control: speed control or torque control |

| Encoder type |

Magnetic encode (TLE5012B E1000 or AS5047D) |

| Speed range |

1:1000 |

| Speed accuracy |

±0.02% |

| Start torque |

0Hz, 200% |

| Torque response |

<5ms |

| Torque accuracy |

±5% |

Basic performances

| Accel/Decel time |

0.00~60000s |

| Switching frequency |

0.7~10kHz |

| Frequency set mode |

communication or analog input control |

| Torque set mode |

communication or analog input control |

| Stop method |

Ramp to stop, coast to stop |

| Communication method |

CAN bus communication |

| Input terminals |

Digital:6 Analog:1 Power supply:1 channel |

| Output terminals |

none |

| Motor Type |

PMSP or IM |

| Motor temperature sensor |

NTC、KTY84、PT1000 |

Unique characteristics

| parameter adjustment and parameter copy/backup through control panel, PC monitoring software upgrade |

| Motor parameters auto-turning, field-weakening control, energy feedback, hill-start assist control and three groups of fault record. |

Overall protections

| Battery over-voltage |

72V |

ov1 |

| Controller over-heat |

90℃ |

oH1 |

| Motor over-heat |

130℃ |

oH2 |

The bearable lowest temperature of controller

|

-40℃ |

oH3 |

| Battery under-voltage |

|

LoU |

| Controller overload |

|

oL1 |

| Motor overload |

|

oL2 |

| Short-circuit between output and aluminum plate |

|

GdP |

| Output phase loss |

|

oPL |

| Encoder disconnected |

|

CLL |

| Auto-tuning failed |

|

tUN |

| Speed bias is large |

|

SPL |

| Current detection abnormal |

|

CtC |

| Power supply is abnormal when running |

|

|

Environment

| Storage temperature |

-40℃~+85℃,GB/T 18488.1 |

| Ambient temperature |

-40℃~+55℃,GB/T 18488.1 |

| Altitude |

0~2000m. De-rate 1% for every 100m when the altitude is above 1000 meters |

| Relative humidity |

5~95%, condensation allowed , GB/T 18488.1 |

| salt spray |

GB/T 2423.17 |

| Vibration |

Sweep vibration and random vibration, GB/T 18488.1 |

| IP grade |

IP65 |

| Insulation strength |

1500V,1min,≤10mA |

| Insulation resistance |

1000V,hot insulation resistance> 10MΩ |

| Safe grounding |

The resistance between controller conductive parts can be reached and the enclosure ground point is less than 0.1Ω |

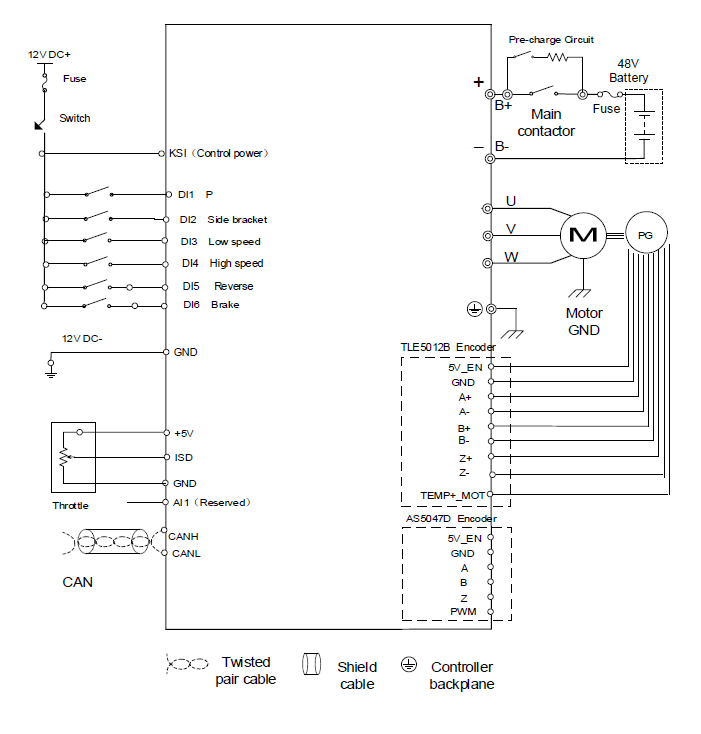

Controller Signal Connector:

The connector and terminals models related to vehicle wiring harness:AMP 770520-1/770854-1

Copper core of cable:0.5~1.25mm2, Outer diameter of insulating layer:1.7~2.7mm

| PIN |

Signal Name |

Definition |

Remark |

| 1 |

TEMP+ |

Motor temperature |

Motor temperature sensor + |

| 2 |

GND |

Magnetic encoder - |

Magnetic encoder - |

| 3 |

5V_EN |

Magnetic encoder + |

Magnetic encoder + |

| 4 |

P |

Park |

12V effective |

| 5 |

5V |

Throttle control power |

|

| 6 |

KSI |

12V battery + switch |

|

| 7 |

CANL |

CANL |

Low end of CAN

|

| 8 |

CANH |

CANH |

High end of CAN |

| 9 |

Z-(PWM) |

Encoder Z- (PWM) |

Connect to Z- when encoder is TLE5012B E1000

Connect to PWM when encoder is AS5047D

|

10

|

A- |

Encoder A- |

|

| 11 |

B- |

Encoder B- |

|

| 12 |

ISD |

Throttle control signal |

0-5VDS |

| 13 |

BC |

Side bracket signal |

When 12V side bracket signal is

enable, the system control is valid

|

14

|

LOW |

Low speed gear |

12V effective |

| 15 |

AI |

Analog signal (Reserved) |

|

| 16 |

Z+(Z) |

Encoder Z+(Z) |

Connect to Z+ when encoder is TLE5012B E1000

Connect to Z when encoder is AS5047D

|

| 17 |

A+(A) |

Encoder A+ (A) |

Connect to A+ when encoder is TLE5012B E1000

Connect to A when encoder is AS5047D

|

| 18 |

B+ (B) |

Encoder B+(B) |

Connect to B+ when encoder is TLE5012B E1000

Connect to B when encoder is AS5047D

|

| 19 |

GND |

Motor temperature sensor - |

Motor temperature sensor - |

| 20 |

HIGH |

High speed gear |

12V effective |

| 21 |

Reverse |

Reverse |

12V effective |

| 22 |

Brake |

Brake |

12V effective |

| 23 |

GND |

Isolated 12V- |

|

Note: Customer shall pay close attention to the items marked by *

Power input & output terminals:

| Terminal Name |

Signal Definition |

Copper core: mm2, Metal terminal/Max size of cable insulation: mm |

Rated voltage/current |

| + |

Battery input + |

25/35,9.5~12 |

300V DC/150Arms |

| - |

Battery input - |

25/35,9.5~12 |

300V DC/150Arms |

| U |

Output U phase |

25/35,9.5~12 |

300V DC/150Arms |

| V |

Output V phase |

25/35,9.5~12 |

300V DC/150Arms |

| W |

Output W phase |

25/35,9.5~12 |

300V DC/150Arms |

Commissioning tools

CAN communication:USB-CAN adapter

Programming computer:Computer equipped with corresponding software:

Top

Top